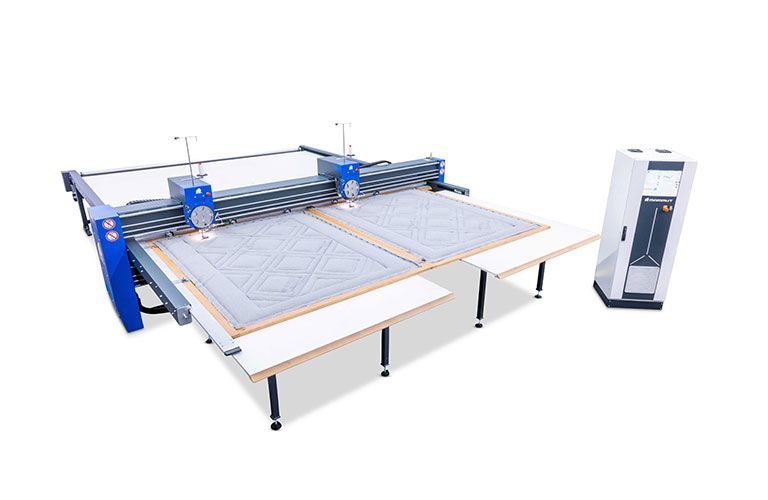

Double Lockstitch Single-Needle Sewing Machine

MAMMUT P2S/P1S

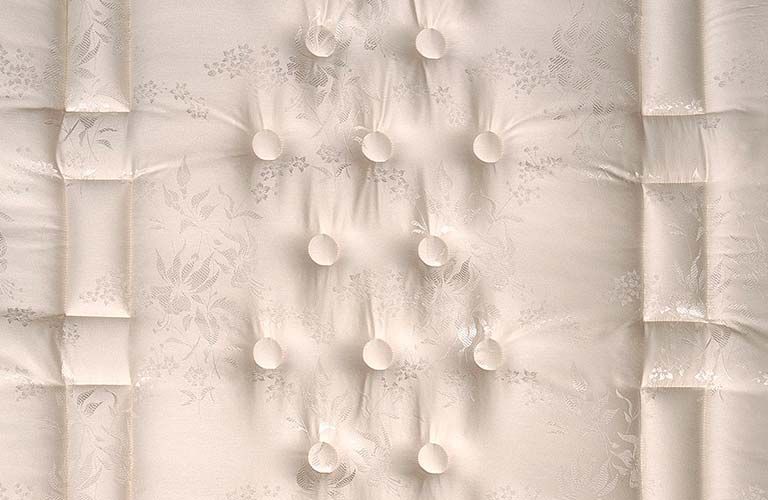

THE SINGLE-NEEDLE SEWING MACHINE WITH TENTERING FRAME FOR EXCLUSIVE QUILTING.

IT COMBINES THE BEST IN SEWING QUALITIES WITH EXTREME SPEED AND EXCELLENT PATTERN PRECISION.

IT IS ESPECIALLY WELL SUITED FOR MATTRESS OR QUILT PRODUCTION IN SMALLER BATCH SIZES.

Double Lockstitch

Featuring a threefold revolving hook with a floating bobbin case, thereby providing non-sensitive settings and a high degree of sewing precision.

Flexibility

Ideally designed for small batch sizes and frequent changes in terms of the materials used.

Versatile handling

Easy accessibility to all operating and setup functions.

Innovation

Singular and specially designed industrial sewing heads for the processing of multi-layered and large surface materials.

Productivity

High output quantity achieved by utilizing a paralleled working process with a double sewing head.

Durability

Extremely stable design of all parts for long lasting durability and a low level of maintenance work.

- A Double-sided guidance system ensures highly precise movements of the tentering frame, even with frequent or oscillating changes of direction

- Especially large needle stroke of 53 mm instead of the standard 40 mm allowing sewing without wrinkles of elastic or very thick materials.

- Presser foot pause manoeuvre allows for pin-point accuracy with thinner needles.

- A second variable use sewing head is available for even shorter quilting times. This way two pieces of fabric can be processed in parallel or one piece can be processed with two sewing heads simultaneously.

- Large bobbin capacity.

Our software, designed in-house by our technicians, as well as our CNC based machine control with a modern touch-screen interface provide all of the current state-of-the art features. Optionally, you may also purchase our CAD based software for pattern programming, Mammut Graphics, which greatly simplifies the work of both the product designer as well as the machine operator.

Our Tele-Service Mammut-Connected Monitoring (Mammut COM) as well as our Mammut-Condition-Based-Maintenance (Mammut-CBM) for preventive maintenance reduce machine downtime. Our enhanced system for plant data collection (Mammut DATA) in connection with a virtual interface to the customer´s ERP system (Mammut LINK) ensures a maximum of process control and reliability.

Further info

Electrical Data

- 3 Phase / 400 V

- 50-60 Hz

- 3,5 KW

Mechanical Data

- 8.350 x 4.550 mm (LxW)

- Weight approx. 1.500 kg

- Compressed air 6 bar

- Air consumption 250 l/min

General Machine Data

- up to 2.650 stitches / minute

- max. sewing area 3.500 x 3.600 mm

- Stitch length 2-8 mm